- OGCI, GCMD, Stena Bulk and a consortium of leading maritime organisations release report demonstrating the technical feasibility of onboard carbon capture and storage (OCCS) technology to reduce shipping’s emissions

- Study finds OCCS technology could reduce Stena Impero’s existing CO2 emissions by as much as 20% per year, with a fuel consumption penalty of just under 10%

- The report identifies practical barriers, such as port readiness, which need to be addressed before OCCS can be widely adopted across the maritime industry

LONDON / SINGAPORE, OCTOBER 10, 2024 – A project assessing the technical feasibility of onboard carbon capture and storage (OCCS) in the shipping sector, carried out by the Oil and Gas Climate Initiative (OGCI), the Global Centre for Maritime Decarbonisation (GCMD) and Stena Bulk together with a consortium of the world’s leading maritime organisations, has concluded that the technology has the potential to help maritime transport significantly reduce its greenhouse gas emissions.

The project, Realising Maritime Carbon Capture to Demonstrate the Ability to Lower Emissions, (REMARCCABLE) was supported by a consortium comprising American Bureau of Shipping, Alfa Laval, Deltamarin, Lloyd’s Register, Seatrium, and TNO. It aimed to assess the viability of deploying carbon capture systems on vessels with minimal impact on operational constraints.

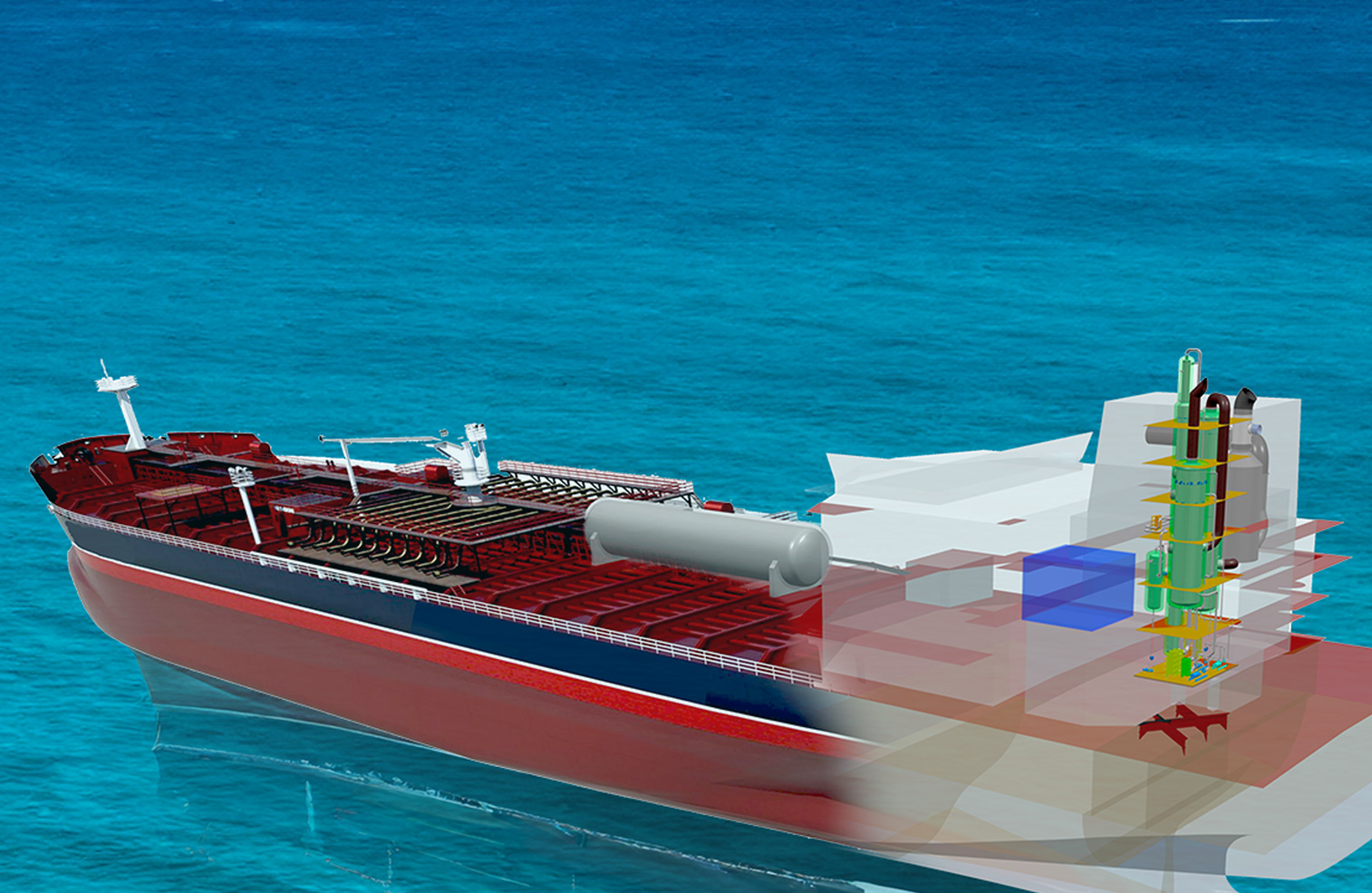

The engineering project analysed the design and cost implications of retrofitting a carbon capture system on the medium-range tanker Stena Impero. It found that the technology could reduce the vessel’s carbon dioxide (CO2) emissions by as much as 20% per year, with a fuel consumption penalty of just under 10%.

The cost of building and installing the full system on the Stena Impero is estimated at US$13.6 million, with an abatement cost of avoided CO2 for the first-of-a-kind prototype evaluated at $769/ton CO2. However, the consortium believes that further research and development will drive down costs, making OCCS increasingly viable for the shipping industry.

The study also looked at incorporating OCCS on newbuild vessels, with the findings that improvements to capture rate and fuel penalty may be achieved using more efficient engines, heat pumps, and alternative solvents.

Dr Michael Traver, head of OGCI’s Transport Workstream, said: “This study is a major milestone in understanding the potential of using carbon capture technology to decarbonize the shipping industry. The technical feasibility demonstrated in the project is highly encouraging.

“OGCI is committed to collaborating with the maritime sector to accelerate the deployment of low-carbon solutions and drive the industry towards a sustainable future.”

Professor Lynn Loo, CEO of GCMD, said:

“OCCS has gained traction in recent years as a feasible approach to meet the 2023 IMO revised GHG emissions reduction targets. However, its adoption faces numerous hurdles, including the need to balance the tension between maximising CO2 capture rates while maintaining commercially acceptable CapEx and OpEx. This study provides quantitative insights on managing the trade-offs between the actual cost of operating OCCS and its emissions reductions potential.

“Just as our eyes are on decarbonising shipping, we must not forget shipping’s critical role in transporting the next generation of energy from where it’s produced to where it’s needed. Our partnership with OGCI will lend an important lens on shipping’s role in the global fuel transition. As our Coalition partner, we look forward to forge pathways to build up the portfolio of viable solutions for shipping to achieve its net-zero targets.”

Loo added: “For OCCS systems to be practical, the industry needs to manage captured CO2 effectively. To this end, GCMD has previously completed a study to define the operational envelope for offloading onboard captured CO2, contributing to the whole-of-system approach to emissions reduction via carbon capture.”

Erik Hånell, President and CEO of Stena Bulk, said: “This may be expensive for first movers, but the consortium believes that further research and development will drive down costs, making OCCS an increasingly viable solution for the shipping industry.

“The results will be instrumental for not only us, but for the whole sector, to evaluate the operational and commercial opportunities, as well as the challenges when capturing CO2 at sea.”

Hånell added: “Together, we can work towards a sustainable future for shipping.”

The consortium partners added that many challenges remain to be addressed.

On the regulatory front, the industry awaits guidance from IMO’s Correspondence Group tasked with developing a framework for OCCS in MEPC 83.

On the operational front, challenges include recurring additional costs due to fuel penalty, amine solvent replenishment, manpower, maintenance and offloading services.

Offloading captured CO2 is in its nascency, with a lack of national and port policies for accounting captured CO2 and its final deposition. There is also a lack of infrastructure at ports to support offloading and storage.

Therefore, collaboration and support from stakeholders across the value chain will be needed to develop offloading infrastructure and onshore storage. Logistical and policy support for permanent sequestration or utilisation of the offloaded CO2 will also be necessary to encourage the adoption of OCCS solutions. The full project report, available both on the OGCI and GCMD includes detailed technical specifications, cost projections, and recommendations for further development and implementation of OCCS technology in the shipping sector.

Notes to Editor

- The consortium comprises OGCI, the Global Centre for Maritime Decarbonisation (GCMD), Stena Bulk, American Bureau of Shipping, Alfa Laval, Deltamarin, Lloyd’s Register, Seatrium, and TNO.

- The final design is estimated to deliver a 20% net reduction in CO2 emissions over a year’s worth of operations, with a fuel consumption penalty of just below 10%.

- The cost of building and installing the full system on the Stena Impero is estimated at US$13.6 million, with an abatement cost of avoided CO2 for the first-of-a-kind prototype evaluated at $769/ton CO2.

- The consortium partners plan to continue collaborating to address challenges and support the development of OCCS technology for the shipping industry

About Oil and Gas Climate Initiative (OGCI)

- OGCI is a CEO-led initiative comprised of 12 of the world’s leading oil and gas companies.

- It aims to lead the oil and gas industry’s response to climate change and accelerate action toward a net zero emissions future consistent with the Paris Agreement.

- Over the past decade OGCI members have demonstrated the essential role that oil and gas companies can play in delivering a net zero future.

- Since 2017, our members have collectively halved methane emissions and cut flaring by 45%, invested $65bn in low-carbon technologies and shared best practices across our industry and other sectors to accelerate decarbonization.

- OGCI’s members are Aramco, bp, Chevron, CNPC, Eni, Equinor, ExxonMobil, Oxy, Petrobras, Repsol, Shell, TotalEnergies.

Media Contact: Selina Williams selinaw@ogci.com / +44 743 615 4850

About The Global Centre for Maritime Decarbonisation

The Global Centre for Maritime Decarbonisation (GCMD) was established as a non-profit organisation on 1 August 2021 with a mission to support the decarbonisation of the maritime industry by shaping standards, deploying solutions, financing projects, and fostering collaboration across sectors.

Founded by six industry partners namely BHP, BW Group, Eastern Pacific Shipping, Foundation Det Norske Veritas, Ocean Network Express and Seatrium, GCMD also receives funding from the Maritime and Port Authority of Singapore (MPA) for qualifying research and development programmes and projects. Since its founding, bp, Hapag-Lloyd and NYK Line have joined as Strategic partners. To-date, over 100 centre- and project-level partners have joined GCMD, contributing funds, expertise and in-kind support to accelerate the deployment of scalable low-carbon technologies and lowering adoption barriers.

Since its establishment, GCMD has launched four key initiatives to close technical and operational gaps in: deploying ammonia as a marine fuel, developing an assurance framework for drop-in green fuels, unlocking the carbon value chain through shipboard carbon capture and articulating the value chain of captured carbon dioxide as well as closing the data-financing gap to widen the adoption of energy efficiency technologies.

GCMD is strategically located in Singapore, the world’s largest bunkering hub and busiest transshipment port. For more information, go to www.gcformd.org.

Media contact: Xingti Liu, Director, Communications | +65 6979 7660 | xliu@gcformd.org

About Stena Bulk:

With offices in seven countries, Stena Bulk is one of the world’s leading tanker shipping companies. The company controls a combined fleet of around 110 vessels. Stena Bulk is part of the Stena Sphere, which has more than 20,000 employees and sales of SEK 60 billion.